Basic Info.

Product Description

Label Automatic Roll to Roll Screen Printing Machine

Machine Description:

User-friendly touch screen control interface in English for maximum operational convenience.

Equipped with two-side dust romoval rollers to ensure dust-free printing in a good quality.

Film material forwarding and printing head stroke is driven by servo motors to ensure high precision.

Three photocell sensors applied for automatic register in multi color printing works.

Quality linear guides are used in the machine to have the printing head move fast and smooth.

Work table with vacuum suction to hold the film firm during printing process, and release it while material forwarding is going on.

Hot air dryer inner length 60M and 80M for option. Heating temperature is adjustable freely.

Automatic roll to roll silk screen printing machine includes a feeder, a screen printing unit and a hot air dryer.

Application: RFID, heat transfer label, labels and stickers, membrane switches, graphic overlay, IMD, IML, FPC, ceramic decals, motorcycle helmet decals, nameplate and non-woven fabrics, etc.

Machine Parameters:

| Model | LTA-3040 | LTA-5060 | LTA-6080 | |||||

| Max. Printing Size | 300x400mm | 500x600mm | 600x800mm | |||||

| Printing Speed | 0~5000 print/hr. | 0~2500 print/hr. | 0~2500 print/hr. | |||||

| Max. Screen Frame Size | 600x800mm | 800x1000mm | 900x1200mm | |||||

| Frame Adjusting Variable | 60mm | 60mm | 60mm | |||||

| Max. Substrate Width | 320mm | 520mm | 620mm | |||||

| Registration Accuracy | ±0.01mm | ±0.01mm | ±0.01mm | |||||

| Air Source | 0.4~0.6mpa | 0.4~0.6mpa | 0.4~0.6mpa | |||||

| Power | 220V, 3KW, 15A | 220V, 3KW, 15A | 220V, 3KW, 15A | |||||

| Printing Material Thickness | 0.02~0.5mm | 0.02~0.5mm | 0.02~0.5mm | |||||

| Weight | 600kgs | 700kgs | 950kgs | |||||

| Overall Dimensions (L*W*H) | 7000x1100x1900mm | 8200x1200x2000mm | 9000x1350x2200mm | |||||

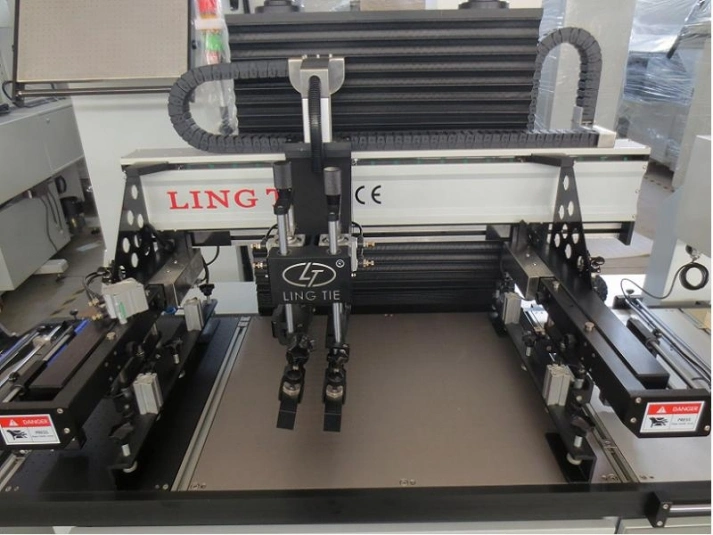

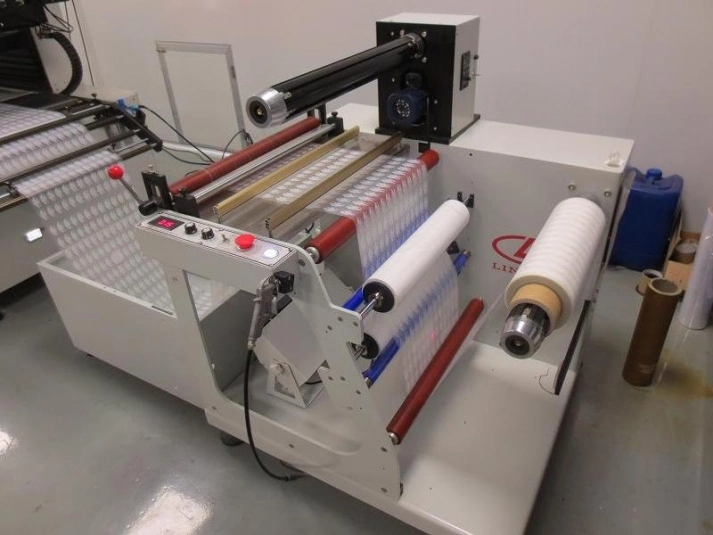

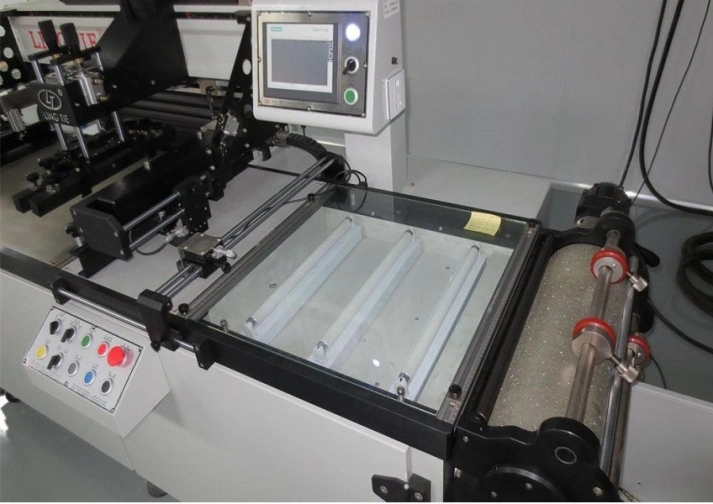

Machine Photos:

Vacuum Table: fix the PET film during printing process. Automatic register system for screen alignment.

Feeder: dust removing, protect film removing, electrostatic eliminating,etc.

Inspection Station: Timely inspection of printing quality to avoid waste.

Rewinding Shaft: After printing, through the tunnel oven drying, automatic rewinding at last.