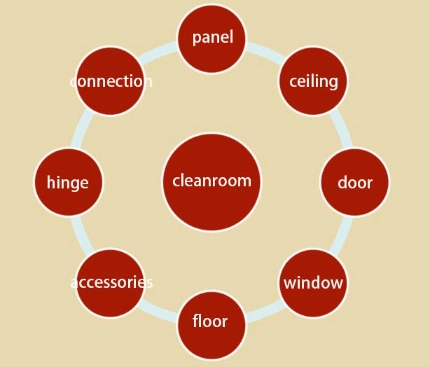

- Overview

- Detailed Photos

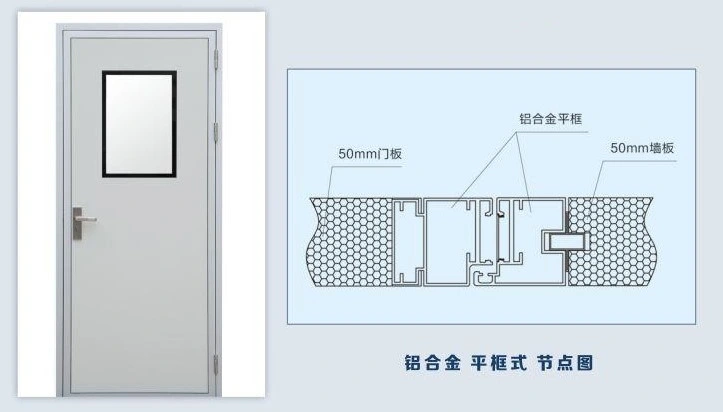

- Product Parameters

- <span style="border:0px;padding:0px;font-size:14px;font-family:Calibri;line-height:21px;"><span style="border:0px;padding:0px;font-size:14px;font-family:Calibri;line-height:21px;">Certifications</span></span>

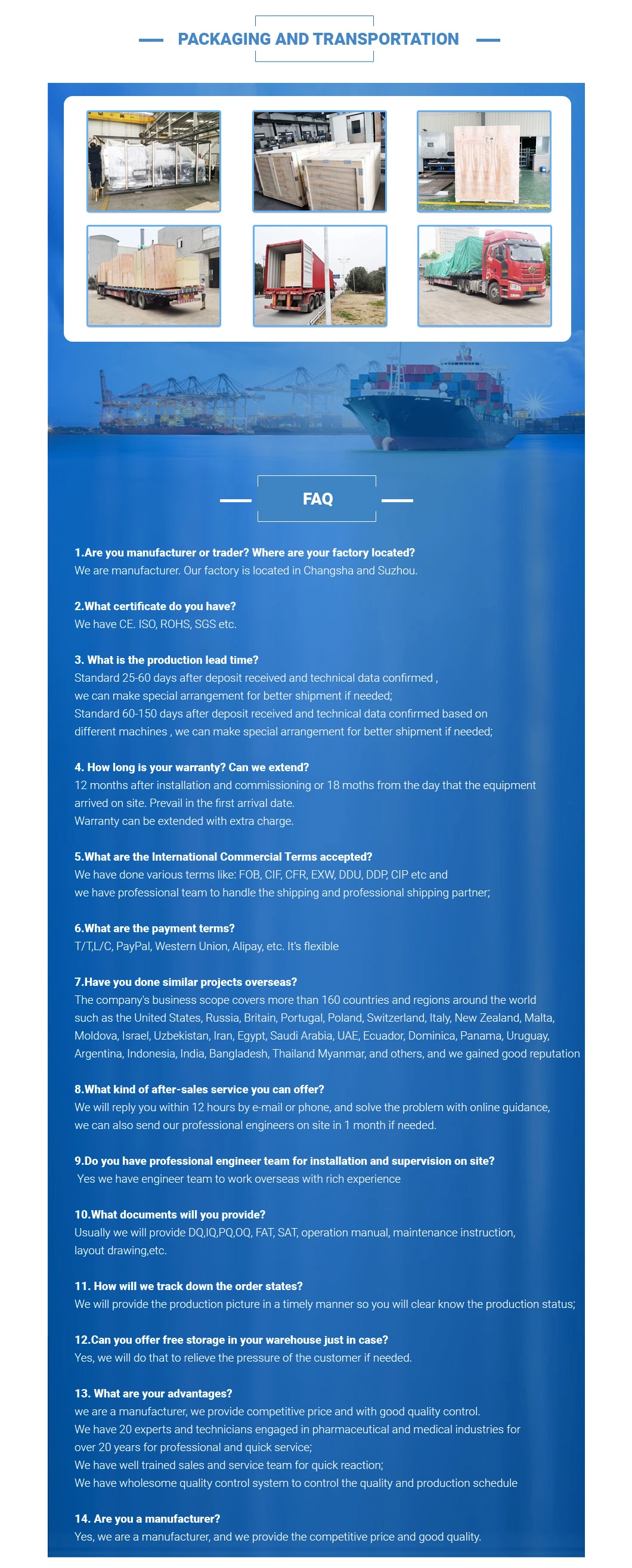

- <span style="border:0px;padding:0px;font-size:14px;font-family:Calibri;line-height:21px;"><span style="border:0px;padding:0px;font-size:14px;font-family:Calibri;line-height:21px;">Packaging & Shipping</span></span>

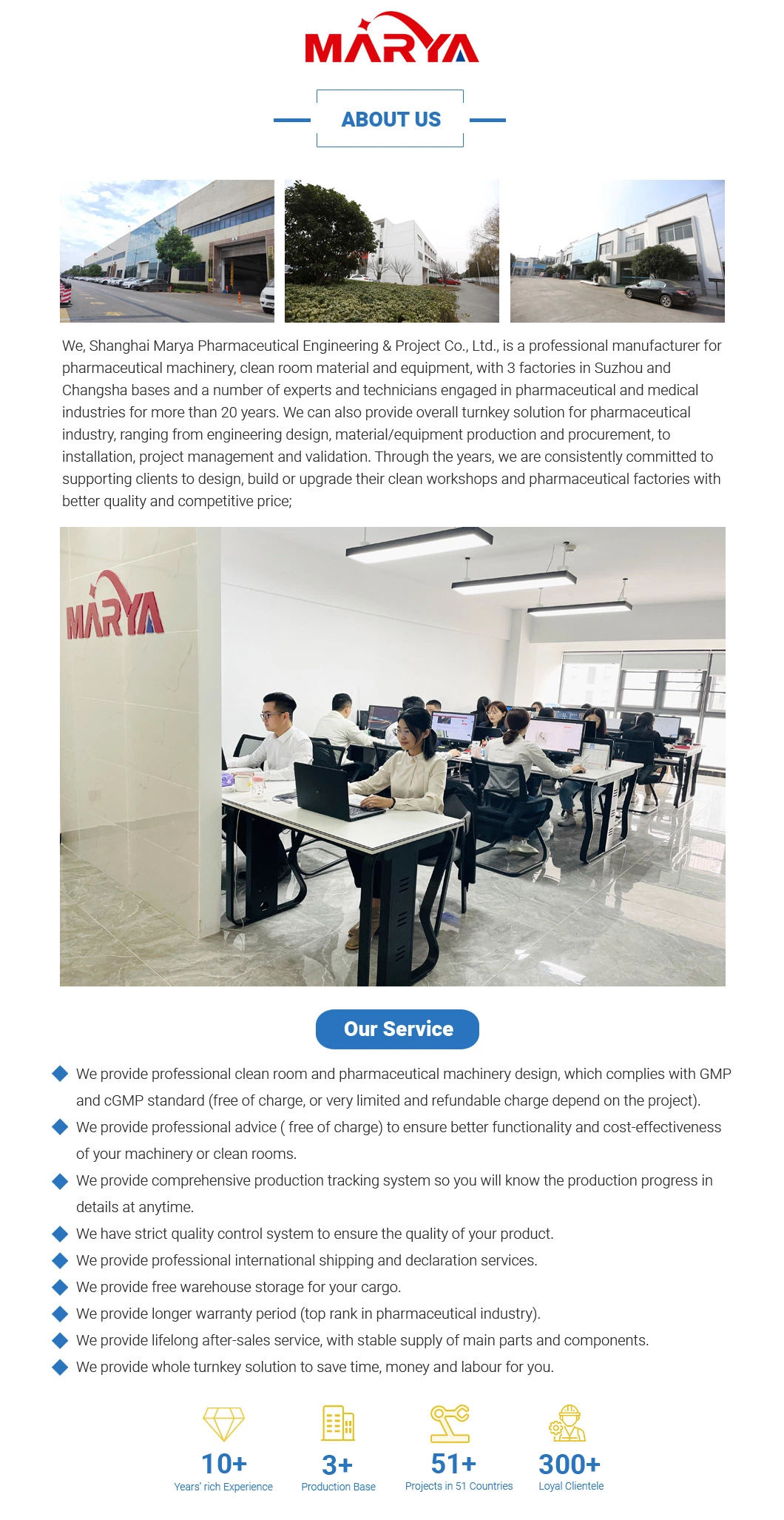

- <span style="border:0px;padding:0px;font-size:14px;font-family:Calibri;line-height:21px;"><span style="border:0px;padding:0px;font-size:14px;font-family:Calibri;line-height:21px;">Company Profile</span></span>

- <span style="border:0px;padding:0px;font-size:14px;font-family:Calibri;line-height:21px;"><span style="border:0px;padding:0px;font-size:14px;font-family:Calibri;line-height:21px;">Our project</span></span>

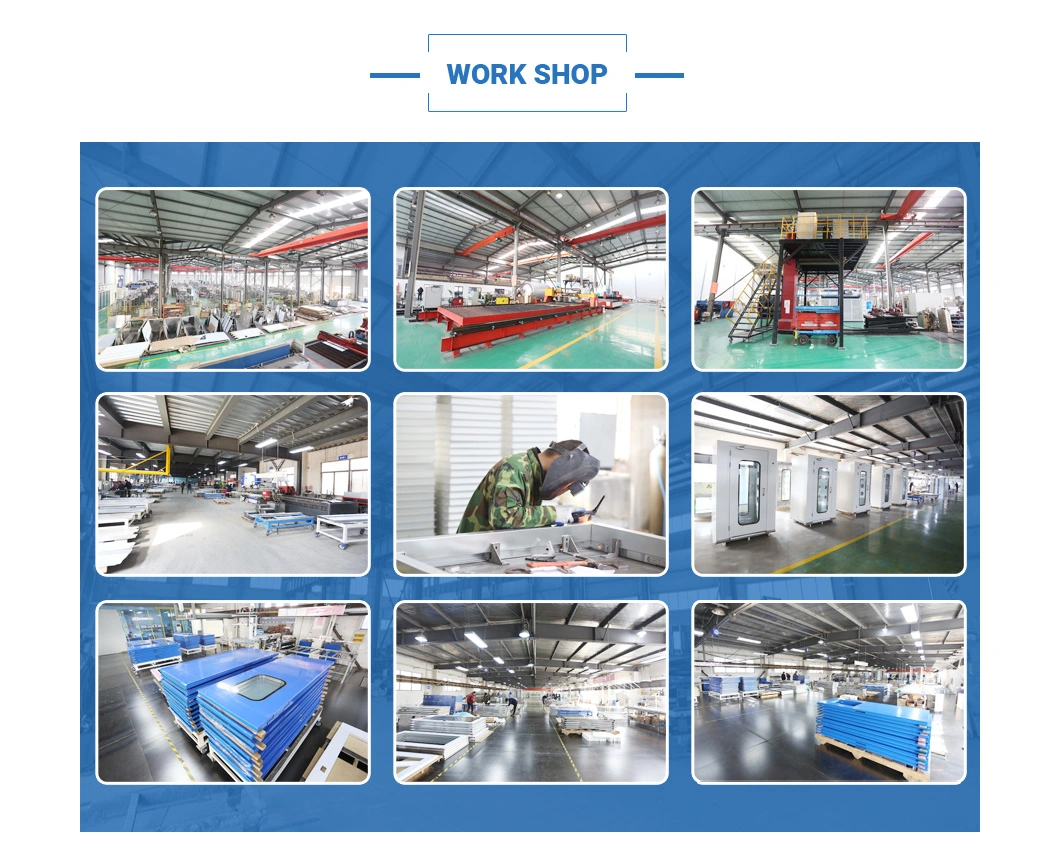

- <span style="border:0px;padding:0px;font-size:14px;font-family:Calibri;line-height:21px;"><span style="border:0px;padding:0px;font-size:14px;font-family:Calibri;line-height:21px;">Our factory</span></span>

Basic Info.

Packaging & Delivery

Product Description

Marya Pharmaceutical Cleanroom EPC One-stop Project Solution for Food Plant Pharm Plant Medical Lab ISO GMP CE Certified

Marya Advantages:

1. Our cleanroom cleanliness level is high, meeting the requirements of GMP, FDA, WHO, and other pharmaceutical standards;

2. Cleanroom is able to realize BMS automatic control;

3. Modular design, fast installation;

4. Construction materials are CE certified;

5. High degree of safety, equipped with safety doors and fire dampers;

6. From A-Z, one-stop service from design to construction verification;

7. Our cleanroom can control the temperature, humidity, pressure difference, the number of dust particles and planktonic bacteria accurately;

8. The brand of HVAC can be specified by the customer;

9. Able to send workers abroad for installation;

10. We have an experienced design team, who are able to design according to customers' different demands.

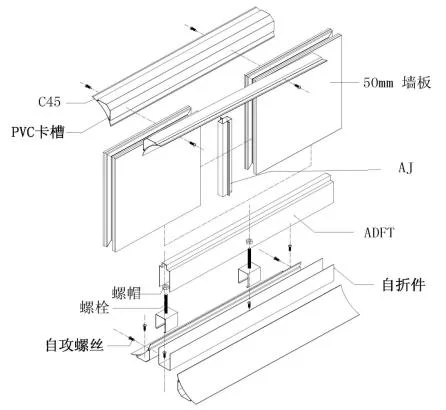

1, cleanroom panel

1.1 Cleanroom panel standard installation and connection: panels are connected with a built-in aluminum keel and PVC square tube, forming a continuous self-supporting structure; seams between two panels are sealed by silica gel. The roof is fixed by M-8 twisted steel and a holder is on the top of the building.

1.2 In order to enhance the strength of the cleanroom roof, we can add gypsum or Mgo panel into the color steel panel. People can walk on it and do various maintenance work. Materials weight needs to be higher than 100 kilograms.

1.3 Cleanroom panel owns high-quality surface materials, which have excellent performances, for example, chemical resistance, wear resistance, scratch resistance, etc.

1.4 Cleanroom panel uses high-quality thermal insulation materials as sandwich materials, and we seal the four edges of panels to avoid pollution due to leakage of sandwich material.

1.5 The cleanroom panel can be pre-embedded according to the design needs to facilitate the passage of various pipelines, and can also be pre-embedded with reinforcing ribs to ensure the strength of the wall panel

1.6 Cleanroom panel has a wall system that is quick and easy to install, flexible and multi-selectable components to meet various requirements, and all components of the wall system are connected smoothly and without protrusions.

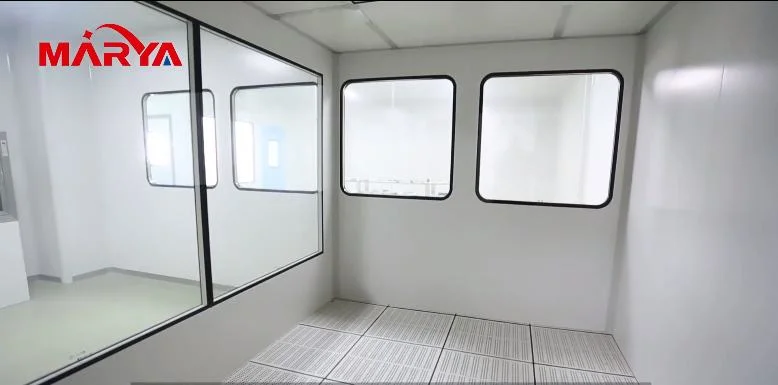

2, Cleanroom door

2.1 The design meets GMP design and safety requirements. No dust, easy to clean. Door seal with high-quality sealing tape, with good air tightness. Easy to clean and air tightness, with strong impact resistance, paint wear resistance, anti-fouling;

2.2 Internal filling paper honeycomb, aluminum honeycomb or polyurethane foam into one;

2.3 Door mold is with high strength, good sealing. Windows are made of high-quality double-layer tempered glass;

2.4 With high-quality 304 stainless steel hinges, can also be customized.

2.5 Handle, silencing bar etc. have different grade for the customer to choose;

2.6 Adopt high quality lifting rubber strip to ensure air tightness;

2.7 Adopt high quality stainless steel door lock, optional stainless steel door suction;

2.8 Open mode: door closers, swipe cards, fingerprints, passwords, remote control;

2.9 Suitable for cleaning workshop, hospital, pharmaceutical factory, food factory, etc.

2.10 Adopting high quality lifting rubber strips to ensure air tightness.

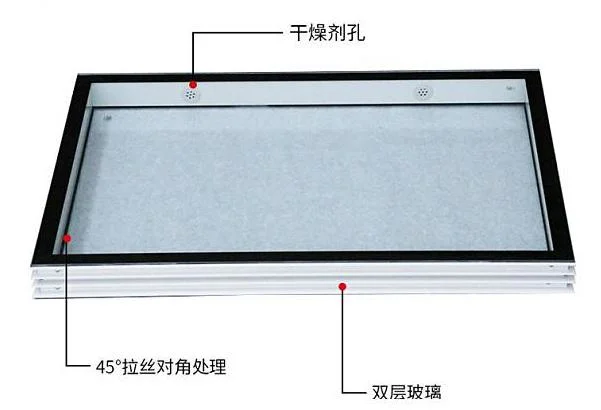

3, Cleanroom window

3.1 Materials: Aluminum frame clean window; stainless steel frame clean window; one-time forming steel frame clean window;

3.2 Cleanroom window shape: round corner clean window, square frame clean window

3.3 Cleanroom window type: midship clean window, wafer window

3.4 Frame color: black printing, white printing

3.5 Glass form: float glass, tempered glass, fireproof glass, yellow light glass, black silk screen is optional on the four sides;

3.6 The cleanroom window is made of double-layer tempered glass. It has good sealing performance, the wall and the window are on the same plane, and the installation is flexible and beautiful.

3.7 Can be made according to different wall thickness, especially suitable for 50-100mm thick color steel plate;

3.8 Application:suitable for clean workshops such as pharmaceuticals, laboratories, food, biology, electronics factories, etc.

3.9 The hollow double-layer clean window can accept non-standard products of different specifications and models, and can choose different shapes and different grades of glass, such as: tempered glass, fire-resistant glass, bulletproof glass, etc.

4, Cleanroom floor

4.1 According to the different needs of the occasion, the ground materials of different materials such as epoxy self-leveling, PVC coiled material and epoxy colored sand ground are used. And it can provide special ground materials with antistatic surface, and at the same time, it can be designed to distinguish different cleanliness levels in different colors in a project.

4.2 PVC ground characters: a)Safety and protection. b)Maintenance convenience.

4.3 Epoxy Self-flowing Floor: The surface is seamlessly painted, dust-free, wear-resistant, impermeable, resistant to heavy pressure, easy to clean, and has a good compressive and impact strength, so the durability and service life of the flooring is relatively long. The thickness of the middle layer of construction can make a partial repair of the unevenness of the base surface, ensuring that the finished surface has a good levelness, improving usability and aesthetics.

4.4 Epoxy colored sand floor: a)Epoxy colored sand floor is a seamlessly integrated new type of composite decorative floor composed of colored quartz sand and epoxy resin. b) It has the advantages of elegant decorative texture, abrasion resistance, compression resistance, chemical resistance, non-slip, fireproof, and waterproof. c)The thickness of epoxy colored sand floor coating is generally 3.0mm and 5.0mm, and the effective service life is more than 10 years. d)Epoxy colored sand floor is mainly used for occasions that require abrasion resistance, strong impact resistance, and high-end decoration.

| No | Name | Material |

| 1 | Door frame | Stainless steel T1.2mm |

| 2 | Door plate | Stainless steel T1.0 mm |

| 3 | Infill | rock wool, PU, paper honeycomb, aluminum honeycomb |

| 4 | Door closer | GMT |

| 5 | View Window | 5mm |

| 6 | Locker | Stainless steel |

| 7 | Drop seal | Auto |

| 8 | Finishing | Powder-coated |

| 9 | Other accessories | Stainless steel hinge, seal |