Basic Info.

Model NO.

KMH-225Ln

Temp. Range

-40oc~+150oc

Temp. Constancy

+/-0.5 Oc/Min

Heater

Iron-Chrome Wire Heater

Blower

Centerifugal Blower

Observation Window

Glass Incorporating Heat Generator

Controller

Touch Screen Programmable Controller

Compressor

Semi-Hermetic Compressor(France Imported Tecumseh)

Cooling Mode

Water Cooled

Working Chamber Volume

225L

Transport Package

Strong Plywood Case, Meet International Standards

Specification

Standard and customized, ISO9001, SGS, CE, TUV, UL

Trademark

KOMEG

Origin

Dongguan, China

HS Code

90321000

Production Capacity

1000 Sets/Year

Product Description

UL recognize High temp. Uniformity Thermostatic Chamber

Applications

Constant Temperature and humidity test chamber is used to test material structure or composite, in the high temperature and ultralow temperature continuous environment.

Toleration of these material to these circumstance. Test chemical change or physical damage caused by their expansion and contraction. Suitable for electronic, LED lighting industry, auto parts, chemical industry, building materials, mobile computers, batteries, plastic, metal, rubber etc. Material.

Under condition of high and low temperature change, test various performance reliability index of related product spare parts and materials for institutions of higher learning, scientific research units etc. Can be used as the basis of improving product or reference.

Features of HIgh temp. Uniformity Thermostatic Chamber

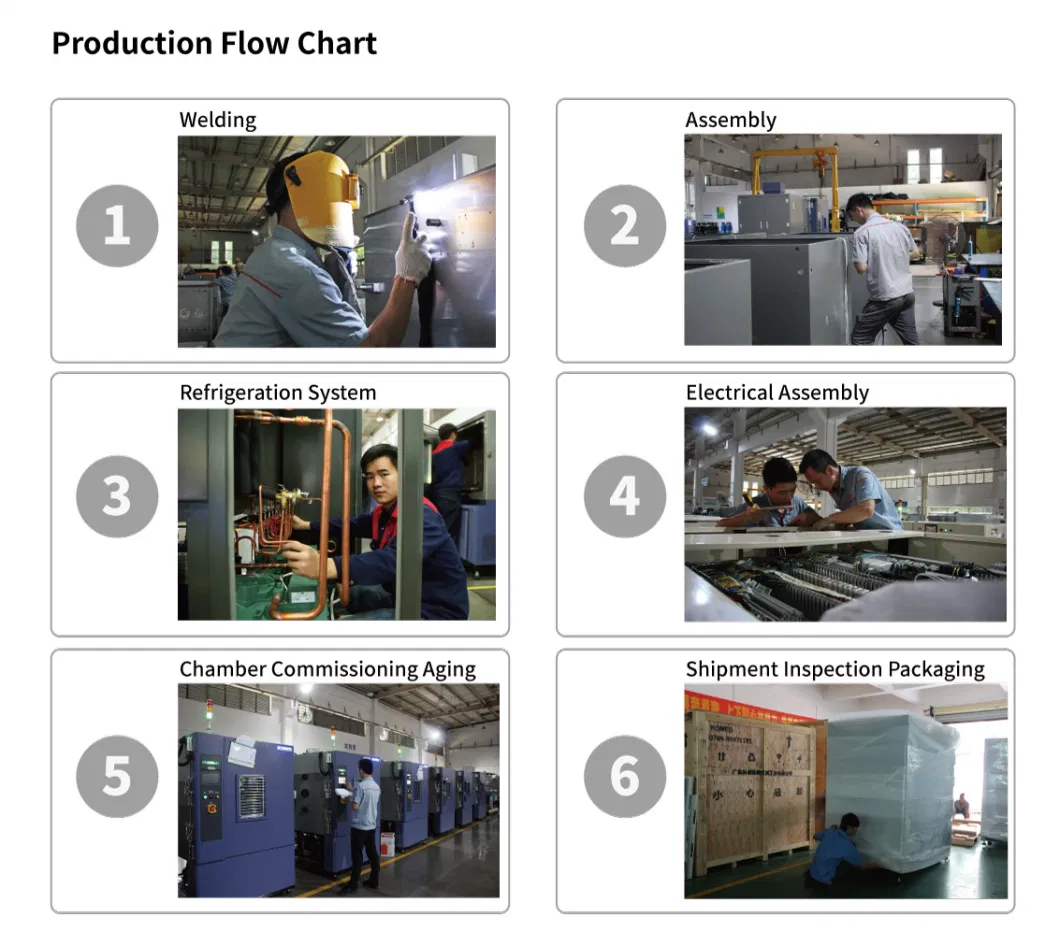

Rational Construction and fast cooling rate

Frequency conversion control of wind speed.

Adopts international brand of imported parts for cooling system to improve operation reliability

Touch screen controller, friendly Man-Machine interface and safety device to ensure simple operation and easy maintenance.

Why Choose Us?

Being a first-class supplier and reliable partner, we are certified to ISO 9001 and got CE approval for all our products. All equipment are 7 x 24 hours tested before delivery. That explains why Komeg is the private brand of choice for many well-known brand enterprises, and also one of the very few designated suppliers who were recognized by many top 500 enterprises. Let Komeg's 23 years of professional experience work for you too.

1. Dedicatetouch and excellent user experience

2. Unique and compact design, top grade appearance, stable performance and easy operation

3. Can simulate a wide rang of temperature and humidity environments

4. Capable of testing large components, assemblies, and finished products

5. Customized sizes and configurations available

6. One year warranties

7. Japan imported UP-10D Seamless Welding Machine, especially for copper pipe welding

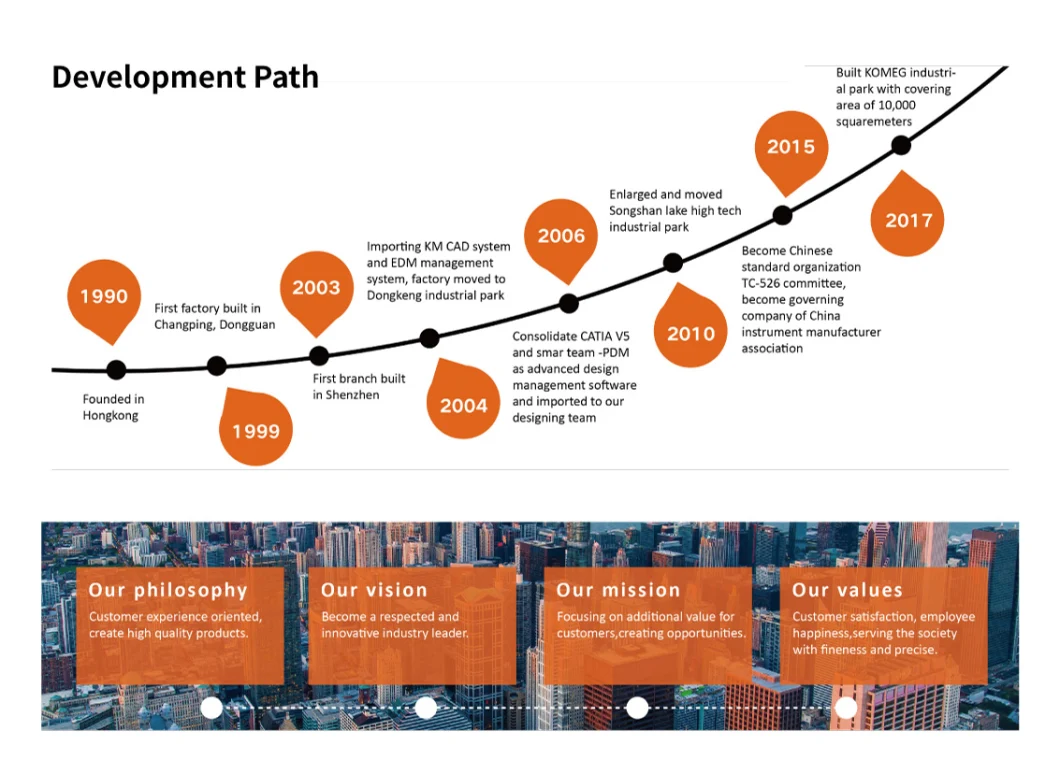

Over 23 Years' Experience

Komeg has been the brand of Komeg Technology Industrial since 1990. We manufacture environmental simulation test equipment for quality-conscious customers. Our factory is located in Dongguan, covering an area of 5, 000 square meters, with over 52 employees including 26 R&D engineers.

We also have offices in Shenzhen and Songshan Lake National Hi-Tech Industrial Development Zone. Our product range includes programmable temperature and humidity chambers, thermal shock test chambers, walk-in chambers, burn-in room and aging test chambers, drying ovens, salt spray testers, as well as custom-made products for laboratories, research institutions, electronic communications and military enterprises.

Better Idea, Design and Quality

We strive for continuous innovation, releasing no less than five new designs each year. Our strong R&D team and skilled workers is the key to our success. No matter it is standard or custom-made project, we have rich experience in handling such so that customers worldwide can benefit more when working with us. And to ensure your specific test standards are met, the key components and parts we are using are imported famous brands. That's why SGS, Konica Minolta, Senko, Midea, TCL and Huawei are among our long-term clients.

Establish a cultural KOMEG, Build a century brand.

Quality conscious enterprise for quality conscious people.

We'd rather explain for the price than apologize for the Quality life long

After-sale Service

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide video-conference. If customers require on-site service, the transport and travel expense shall be borne by customer.

| Model | 225SL5 | 225SL10 | 408LS5 | 408SL10 | 1000SL5 | 1000SL10 | 1000SL5 | 225LL5 | 225LL10 | 408LL5 | 408LL10 | 1000LL5 | 1000LL10 | |

| Working Chamber Volume(L) | 225 | 408 | 1000 | 225 | 408 | 1000 | ||||||||

| Temp. Change Rate º C/Min | 5 | 10 | 5 | 10 | 5 | 10 | 15 | 5 | 10 | 5 | 10 | 5 | 10 | |

| Temp. Range | -70º C~+100º C(Rapid Temp. Change-55º C~+85º C Full Linear Control) | -70º C~+100º C(Rapid Temp. Change-40º C~+85º CFull Linear Control) | ||||||||||||

| Humidity Constancy | ± 0.5º C | |||||||||||||

| Temp. Constancy | ± 3.0º C | |||||||||||||

| Interior Material | Stainless Steel Plate(SUS304) | |||||||||||||

| Exterior Material | Baked painting steel or stainless steel(SUS304) | |||||||||||||

| Insulation Material | Rigid polyurethane Foam+glass fiber wool | |||||||||||||

| Compressor | Semi-hermetic Compressor | |||||||||||||

| Cooling Mode | Water Cooled | |||||||||||||

| Control system | Balanced Temperature & Humidity Control System (BTC type) | |||||||||||||

| Ambient Temp. | +5º C~+35º C | |||||||||||||

| Heater | Iron-chrome wire heater | |||||||||||||

| Blower | Centrifugal Blower | |||||||||||||

| Observation Window | Glass incorporating heat generator | |||||||||||||

| Temp. Sensor | PT-100 | |||||||||||||

| Controllor | Touch screen programmable controller | |||||||||||||

| Safety Devices | Over pressure, over heat and over current protection for compressor, over temp. protection, over load protection for blower, hydraulic and water lack protection, leakage protection | |||||||||||||

| Standard Sccessories | Sight window, Cable port ( | |||||||||||||